New trend of ultra-thin cutting wheels, Camel Abrasives takes you to the world of grinding

2025-05-28

New trend of ultra-thin cutting wheels, Camel Abrasives takes you to the world of grinding

In modern industry, the continuous advancement of grinding technology has led to an increasing demand for cutting tools. In particular, ultra-thin cutting wheels, with their lightness and high efficiency, have quickly become the new favorite of the market. Against this background, as a representative of Zhejiang louvre blade manufacturers, Zhengbo Abrasives shoulders the mission of combining new technologies with market demand and guides us to swim in the vast world of grinding.

The charm of ultra-thin cutting wheels

Imagine that when you are processing metal materials, traditional cutting tools always bring a lot of heat and chips, which is not only inefficient, but also easy to cause material waste. The emergence of ultra-thin cutting wheels just solves these problems. Their thickness is usually between 0.1 and 1 mm. It is precisely because of this ultra-thin design that the heat generated during cutting is greatly reduced, the chips are also less, and the material loss is greatly reduced.

Changes brought by new technologies

With the continuous innovation of technology, the manufacturing process of ultra-thin cutting wheels is also constantly improving. Zhejiang grinding wheel manufacturers not only innovate in materials, using more wear-resistant diamond coatings, but also introduce modern computer control systems into the production process. This means that each grinding wheel can maintain high-precision thickness and size, improving the stability and safety of cutting.

Changes in market demand

Today, the market demand for ultra-thin cutting grinding wheels is rising sharply. This is not only because they can improve cutting efficiency, but also save costs for users. In the context of economic globalization, manufacturers have also realized that providing high-quality products is the foundation for a foothold in the market. Therefore, Zhejiang grinding wheel manufacturers have established their market position in this competition with technological innovation and high-quality services.

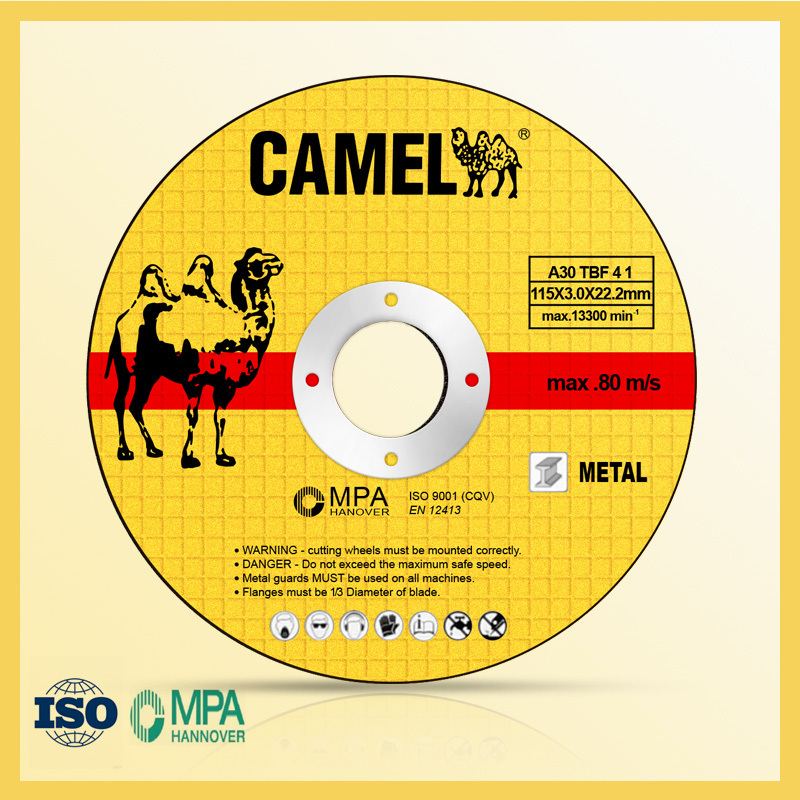

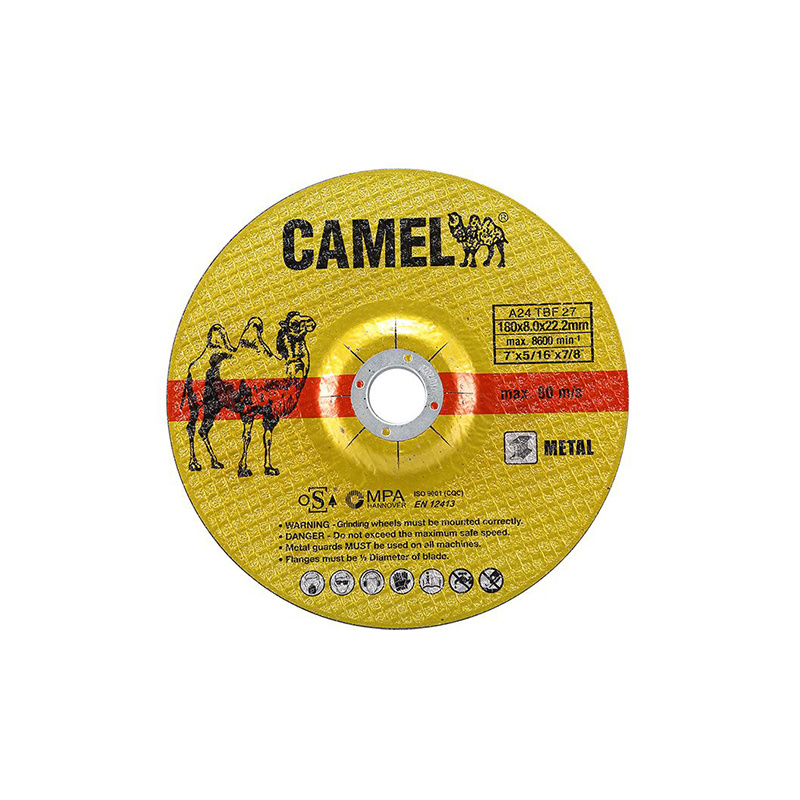

The role of Camel Abrasives

As a pioneer in the industry, Camel Abrasives is not only committed to the research and development and production of ultra-thin cutting grinding wheels, but also pays more attention to interaction with users. Through in-depth communication with customers and understanding the various problems they encounter during use, Camel Abrasives can continuously optimize products to meet market needs. This user-centric concept has established a good reputation in the industry.

Future Outlook

Looking to the future, the market for ultra-thin cutting grinding wheels will be even broader. With the continuous development of science and technology, the performance of grinding wheels will be more superior and the scope of application will continue to expand. Zhejiang grinding wheel manufacturers will continue to explore new possibilities of materials and processes in this process. Camel Abrasives plans to launch more high-performance products to meet the needs of users in different fields.

Summary

In short, the rise of ultra-thin cutting wheels marks a major change in grinding technology. Zhejiang grinding wheel manufacturers play an indispensable role in this process. Camel Abrasives will continue to lead us in the world of grinding, provide users with more efficient and safer cutting solutions, and promote the progress of the entire industry.

So, are you ready to embrace this new trend and experience the revolutionary changes brought about by ultra-thin cutting wheels?

Related Blogs

2025-04-08